Adding new strengths

Additive manufacturing center creates new opportunities for innovations and partnerships

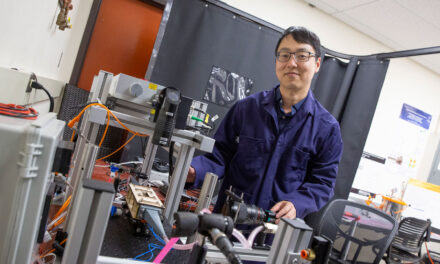

The largest additive manufacturing research facility in the southwest is taking shape at the Polytechnic campus, thanks to a partnership between Arizona State University’s Ira A. Fulton Schools of Engineering, Honeywell Aerospace, Concept Laser Inc., PADT Inc., and Stratasys Ltd.

The 15,000-square-foot center is home to $2 million of cutting edge plastic, polymer and metal 3D printing equipment, along with advanced processing and analysis capabilities that will allow students, faculty and industry partners stay on the forefront of the rapidly growing additive manufacturing sector.

Additive manufacturing is the process of creating a 3D-modeled object layer-by-layer via computer control. While various methods can be used, such as melting or softening materials, fusing powders using a laser or curing liquid materials, all technologies successively layer the raw material until an object is complete.

“This provides a unique opportunity for us to enhance our industry partnerships, and also provide the capability for us to do additional research and enhance our education programs,” said Ann McKenna, director of the Polytechnic School. “With so few of these types of centers, this really positions us regionally to be the go-to place that can work with academic partners, federal agencies and industry to advance a new and emerging field. It really puts in place that structure that not only advances ASU, but the economic growth of Arizona as well.”

As part of their continued investment in the facility, Honeywell Aerospace has the opportunity to outsource research and development that can’t currently be staffed.

“Honeywell is thrilled to be participating in the opening of the new additive manufacturing laboratory at the Polytechnic campus. For many years we have worked with ASU seniors on their Capstone projects with three of these projects this school year additive manufacturing focused,” said Don Godfrey, Engineering Fellow for Additive Manufacturing at Honeywell Aerospace. “In addition to access to our own additive manufacturing operations, we have provided mentorship to students in the program and assisted in the procurement of one machine for the schools new lab. We look forward to growing our relationships with the university in developing brilliant minds to tackle and overcome industry challenges associated with aviation and additive manufacturing.”

By taking advantage of research opportunities, students can better position themselves as more competitive hires once they graduate.

“There’s an insufficient talent pipeline going into manufacturing engineering and these companies need knowledge about these new technologies,” said Malcolm Green, associate director of corporate engagement at the Fulton Schools. “They need to recruit the next generation of manufacturing professionals, so we’re serving the needs of industry and only through partnership can we do that.”

The Polytechnic School is a natural home for the center. It offers the only manufacturing engineering undergraduate degree in Arizona and one of only 21 in the United States.

“This center draws on manufacturing expertise that resides at the Polytechnic School and helps build the infrastructure to support our faculty, as well as faculty in other schools within the Fulton Schools,” said McKenna. “We envision this facility as a way of setting up a collaborative model for how we can work across the Fulton Schools, and it can be a signature activity here at the Polytechnic campus.”

Read more about the Polytechnic School in their annual report.