Fluidic Energy: ASU academic start-up attains global reach

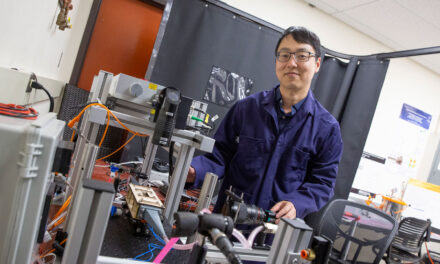

Above: Fluidic Energy is the first company to deliver rechargeable metal-air battery technology in high production volumes for commercial, load-shifting applications. Photo courtesy of Fluidic Energy.

Cody Friesen’s alternative research team at Arizona State University set out to create an energy storage breakthrough that would dramatically reduce costs and eliminate toxic and rare metals in batteries. The solution was found by innovating a way to make zinc-air batteries rechargeable — a solution that launched Fluidic Energy Inc. as a private company now set to power 500 remote Indonesian islands.

The “500 Island Project,” one of the largest rural electrification projects in the world, will employ Fluidic’s unique, sustainable energy system to provide electricity to 1.7 million people in 325,000 households — many of which have never before had a reliable energy source. Fluidic’s partnership with Caterpillar Inc. and PT Perusahaan Listrik Negara (PLN), Indonesia’s state-owned electric company, was announced in October.

The micro-grid network being deployed in Indonesia is a “much smarter grid” than those currently in use, explains Friesen. “It’s a stand-alone system, which makes it ideal in remote locations like the islands of Indonesia. We use solar technology to recharge the batteries, and we’ve eliminated the toxins associated with diesel generators and lead.”

More important, the system is reliable in an environment where reliability is critical. “It can withstand hot climates and heavy usage loads without the deterioration you find in lead-based batteries or the high costs associated with diesel,” Friesen emphasizes. “When you are on a remote island, you can’t just plug into a larger power grid.”

Friesen, an ASU associate professor whose work allowed him to found Fluidic, says he was headed elsewhere after completing his doctorate at MIT in 2004. But “some interesting things” were happening at ASU, where he’d earned his bachelor’s degree in materials science and engineering in 2000, intrigued him.

“President Michael Crow was talking about shaking up the academic model to go solve big world problems,” he points out. “ASU was creating new models for expanding academic impact into the marketplace.” So Friesen joined the faculty at the School for Engineering, Matter, Transport and Energy (SEMTE). The Office of Knowledge and Enterprise Development (OKED) and Arizona Technology Enterprises (AzTE) helped Fluidic Energy to spin-out, and the company has now raised about $150 million in equity financing from investors.

In 2009, ASU and Fluidic were awarded a joint $5.1 million grant from the Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-e), which funds high-potential, high-impact energy technologies. OKED and AzTE were instrumental in navigating licensing and other aspects of the project, Friesen says. In 2011, Fluidic was granted a second ARPA-e project grant, this time $3.75 million, to focus on aspects of making the batteries grid-capable.

The process of developing a new, sustainable source of energy began broadly. “How do we store energy at a lower cost while improving reliability and sustainability,” is the question that launched the journey, Friesen recounts. Ultimately, it became clear that an old technology, zinc-air batteries, could be a lower-cost, safer alternative to lead acid batteries or diesel generators. Zinc-air batteries have been around since the 1920s, now found commonly in the form of non-rechargeable hearing aid batteries.

“For a long time people had been creating Rube Goldberg devices, complex approaches attempting to solve the problem of rechargeability in zinc-air batteries. We wanted an elegant solution that would result in retaining the ultra-low cost basis of this technology space while also enabling extremely long life,” Friesen says.

But there were challenges. “There were two major components to making zinc-air batteries feasible: First, solve the dendrite problem – dendrites form ice-like spikes around the electrodes and, when they migrate, they can short out the battery; and second, find an alternative to water-based electrolytes so the batteries are stabilized and rechargeable.”

In late 2007, Friesen and his team developed a hierarchical anode that blocks the dendrites from causing a short. Once the team solved the stabilizing and recharging issues by developing advanced ionic fluid electrolytes instead of water-based, the team had a highly reliable, sustainable, clean technology ready to develop for the market.

And develop they did. Fluidic has been delivering batteries to thousands of sites across Southeast Asia and Latin America for the past five years, and is recognized in the industry as the long-duration energy storage leader.

This was made possible by a team of “rock stars,” says Friesen. “Our first two employees, Joel Hayes and Dave Miller, really set the trajectory. We quickly added a set of remarkable scientists and engineers, Todd Trimble, Ph.D., Grant Friesen, Ramkumar Krishnan, Ph.D., who is the current CTO, Kurt Kenzler and Curtis Burt.” That initial team had a compliment of six ASU degrees, and degrees from Purdue, MIT, Johns Hopkins and range of other top schools, explains Friesen. “Without that founding team, we would have gone nowhere.”

Fluidic’s batteries deliver a longer cycle between recharges, providing up to 24 hours of energy compared to the one hour or so from lead-acid or lithium batteries. And, the 500 Island system’s remote monitoring setup allows technicians to identify poorly performing cells and take them offline for maintenance.

The company, which provides on-site training to installation and service personnel, has established manufacturing facilities in Indonesia. Fluidic was recognized in January as one of the Global Cleantech 100 — private firms positioned to solve tomorrow’s global clean technology challenges, and its Scottsdale operations continue to employ more than 100 high-tech professionals locally.

“The support we’ve received from the entire ASU community, from former Fulton Schools Dean Paul Johnson to current Dean Kyle Squires to OKED and AzTE, has been phenomenal,” says Friesen. “Many of my colleagues who’ve watched ASU thrive over the past ten years are in awe.”

Media Contact:

Terry Grant, [email protected]

Ira A. Fulton Schools of Engineering